*This portfolio presents my work in a manner that respects the Non-Disclosure Agreements (NDA) I am bound to. Details have been generalized and do not disclose any sensitive information. The information is for demonstrative purposes only, aiming to highlight my capabilities while upholding the highest standards of professionalism and confidentiality. For any inquiries or clarifications, please get in touch with me directly.*

Following the conferral of my Undergraduate degree in Product Design and Computer Science, I was poised to start my Graduate program studying Mechanical Engineering. However, due to the misalignment between my Undergraduate and Graduate studies, I wanted to take some time to learn more about what Mechanical Engineering meant to me. More specifically, I wanted to hone the manufacturing sub-components I learned about as a product designer and have work experience in a relevant field.

Following an extensive application process, I was selected as the Mechanical Engineering contractor for Buoyant Aero, a startup company focused on bringing a new electric scooter model to market. Due to the terms of my NDA, I am not able to share many details of the specifics of my work experience, but I will share high-level takeaways.

During this three-month position, I had a hand in designs, calculations, CAD sketches, and physical manufacturing.

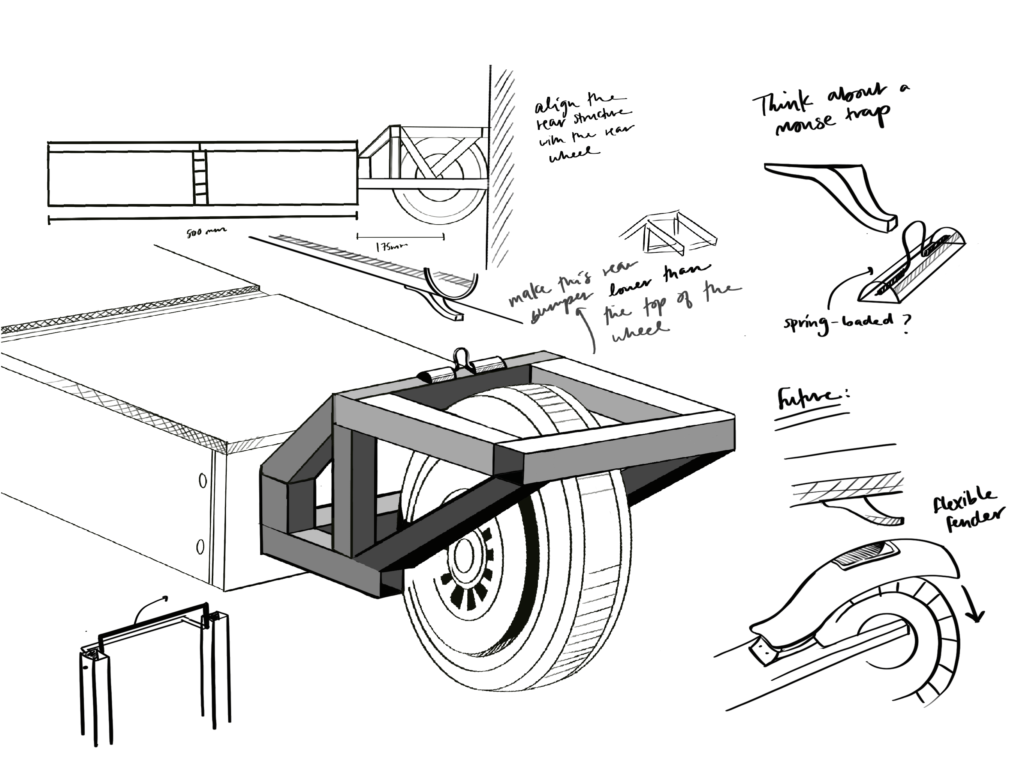

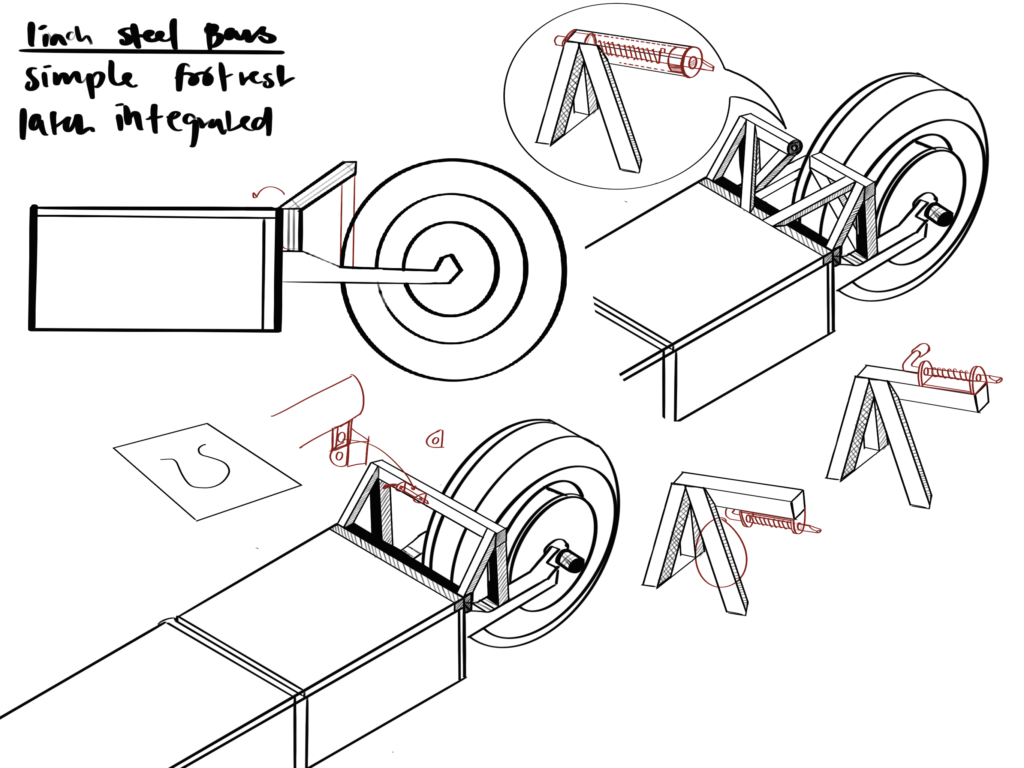

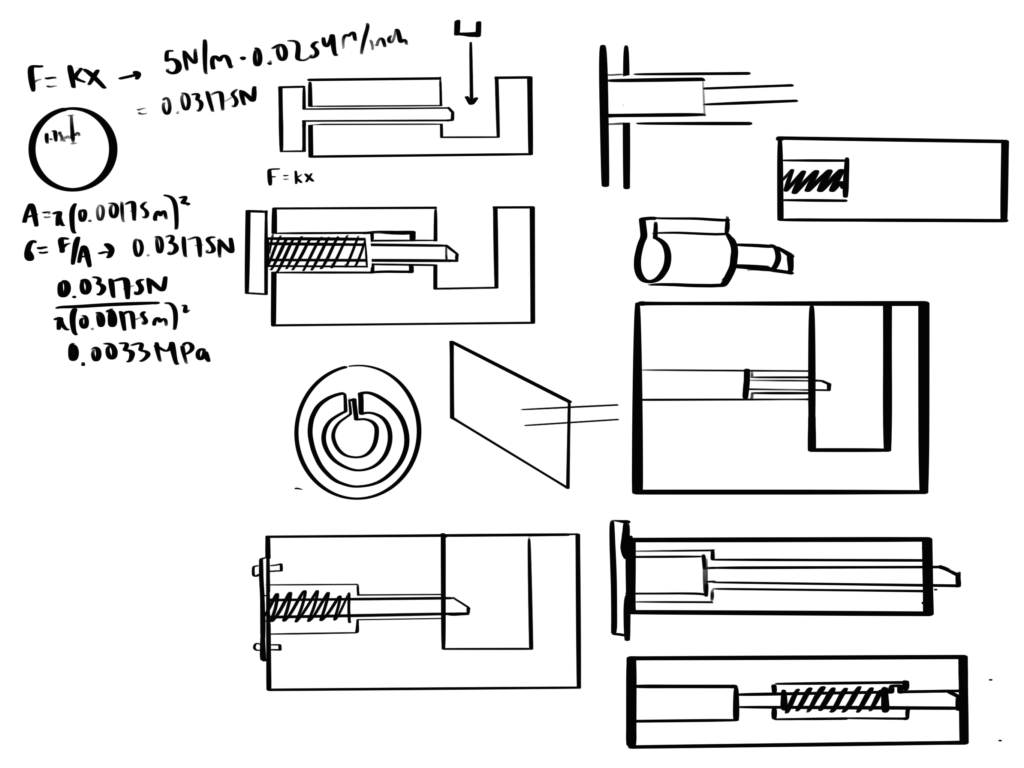

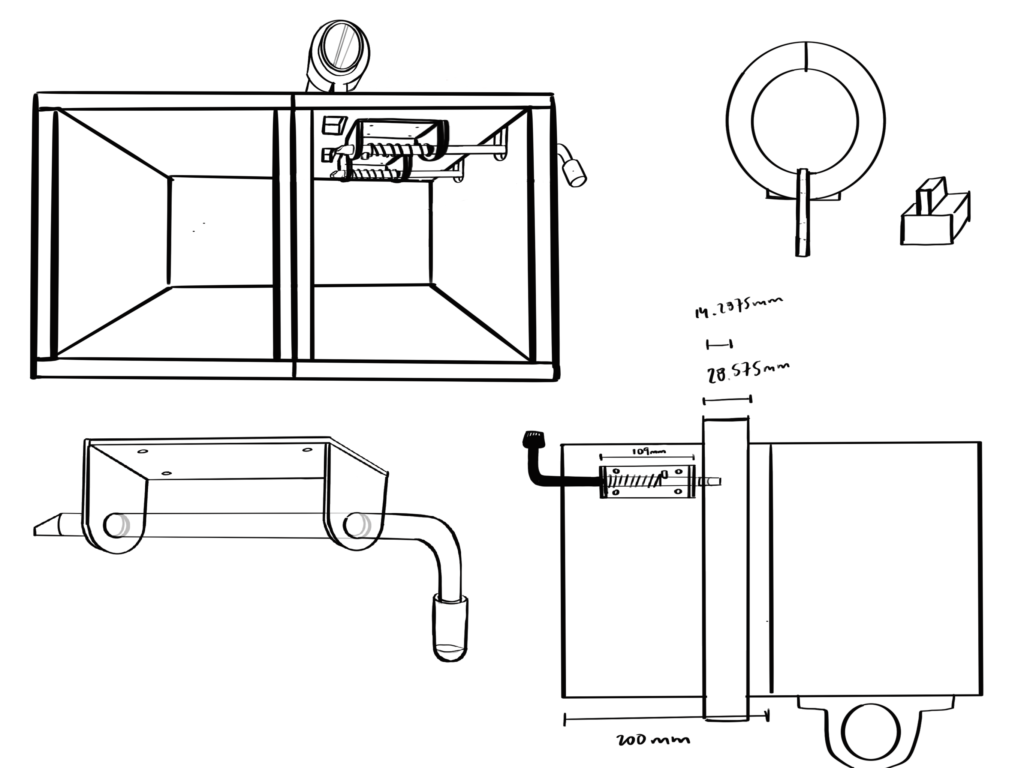

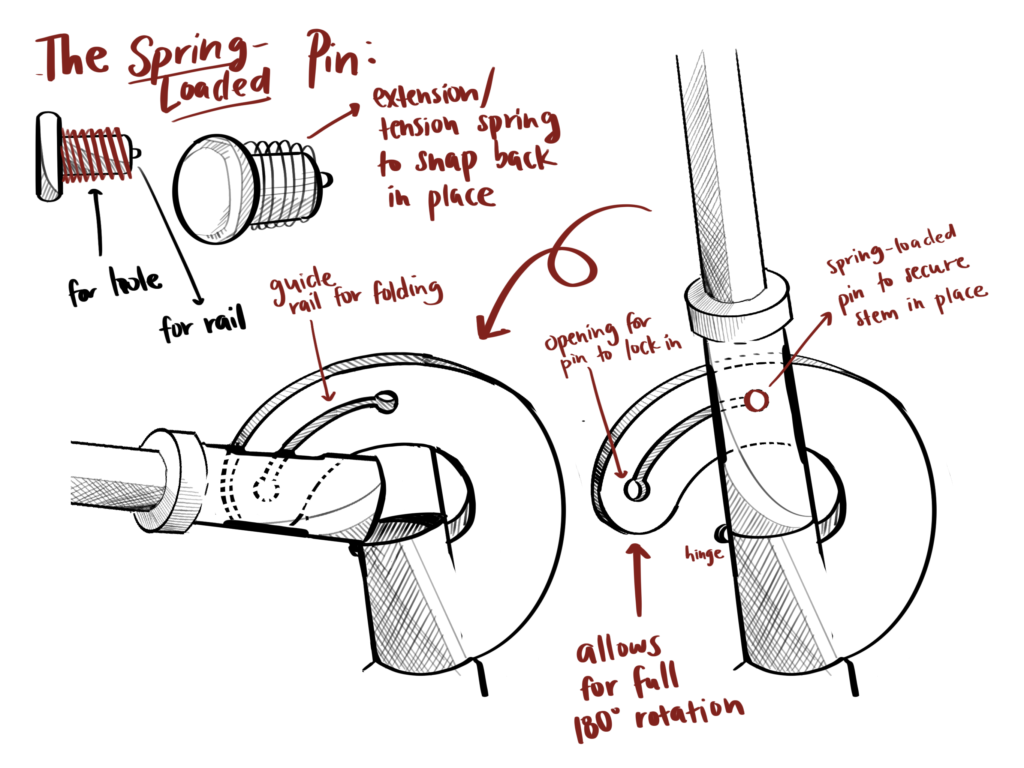

Sketches

I created many sketches, from concept designs to FBDs–fashioning aesthetics with mechanical principles to understand how the scooter design could function and improve. In addition to those shown, I created low-fidelity sketches to ideate new ideas to implement within the scooter design and high-fidelity sketches to hone the aesthetic vision of the final design.

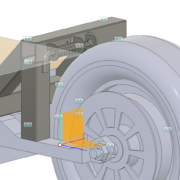

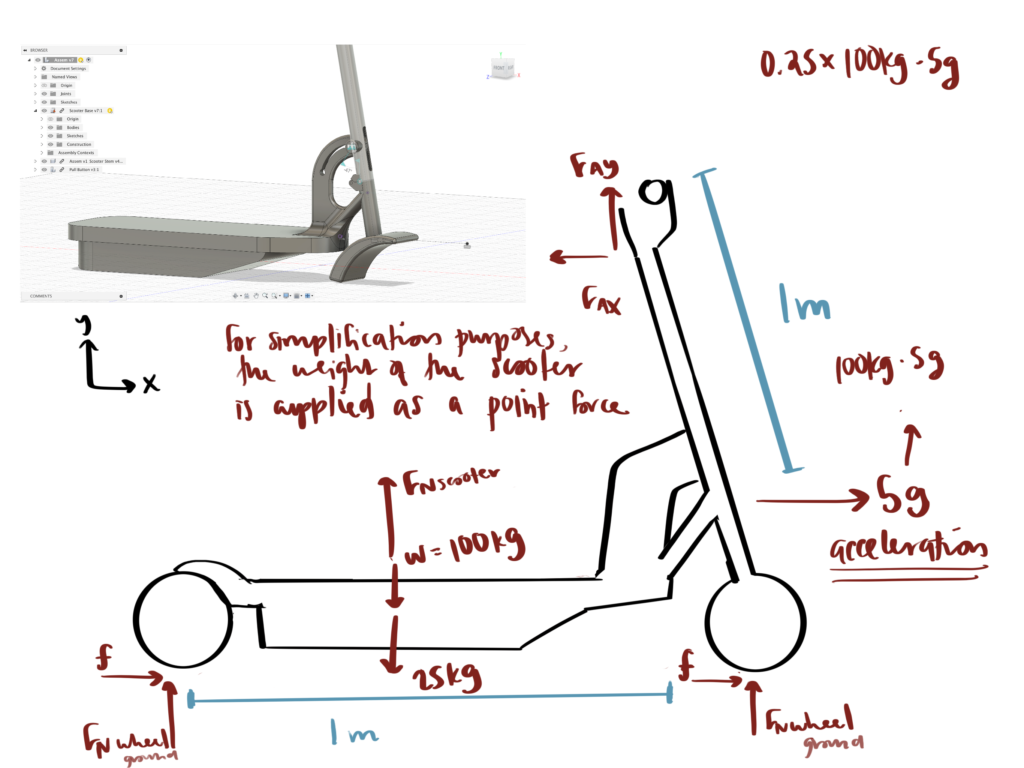

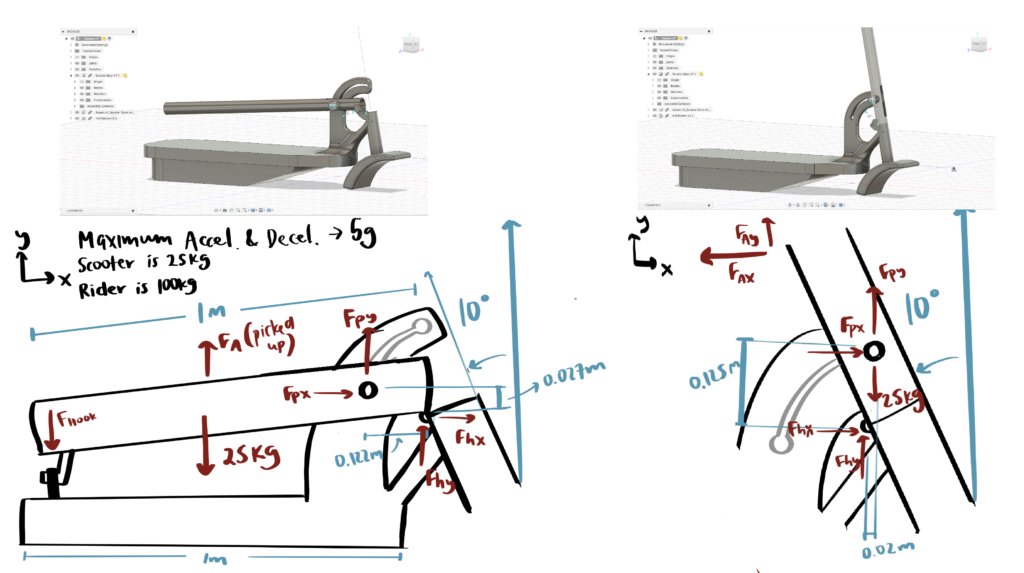

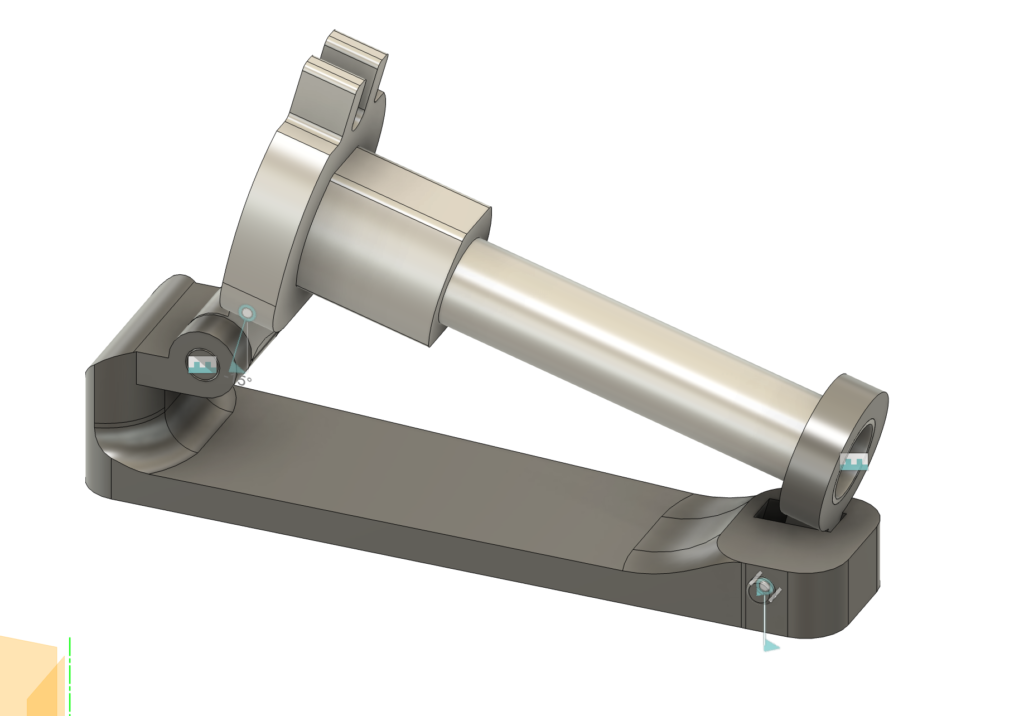

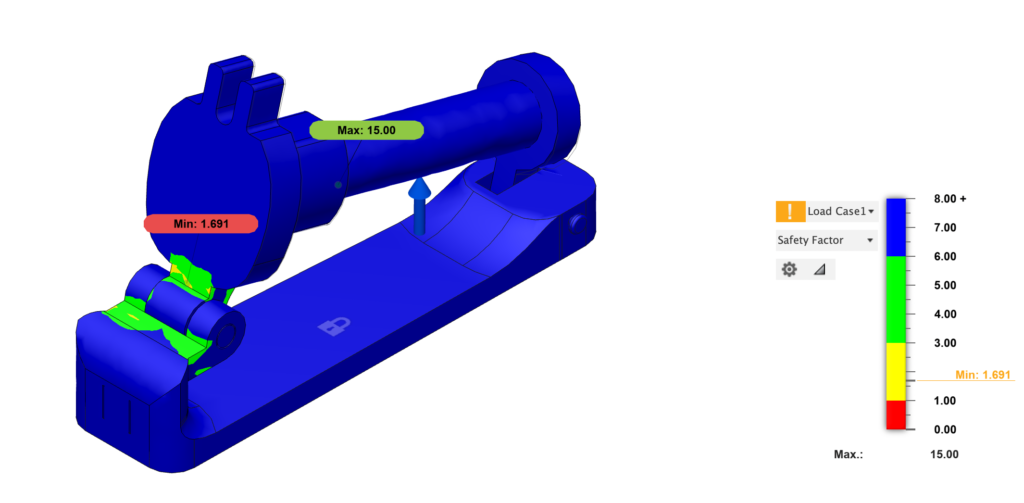

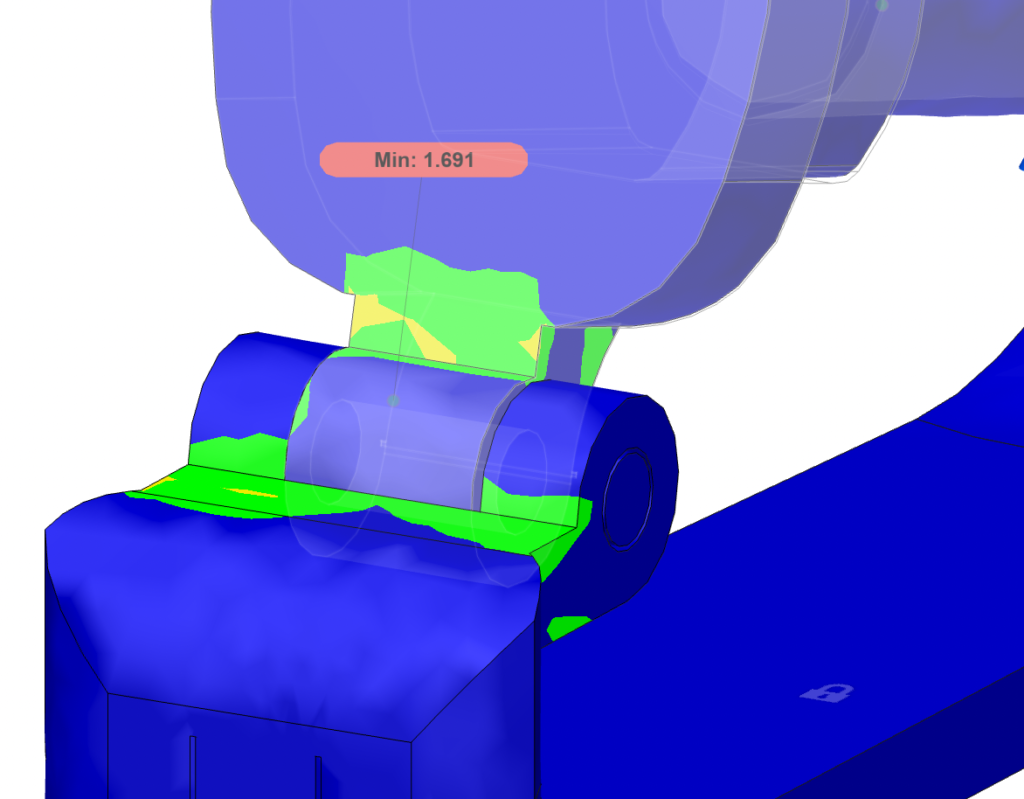

CAD

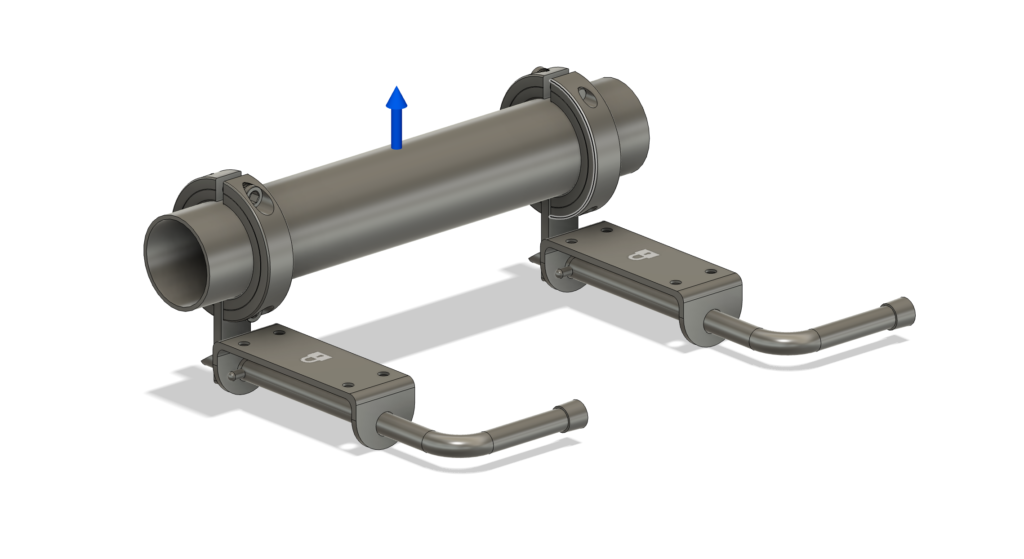

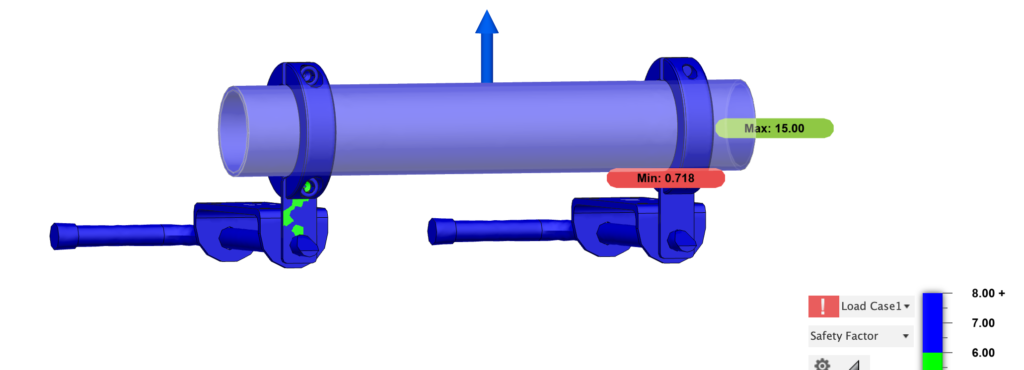

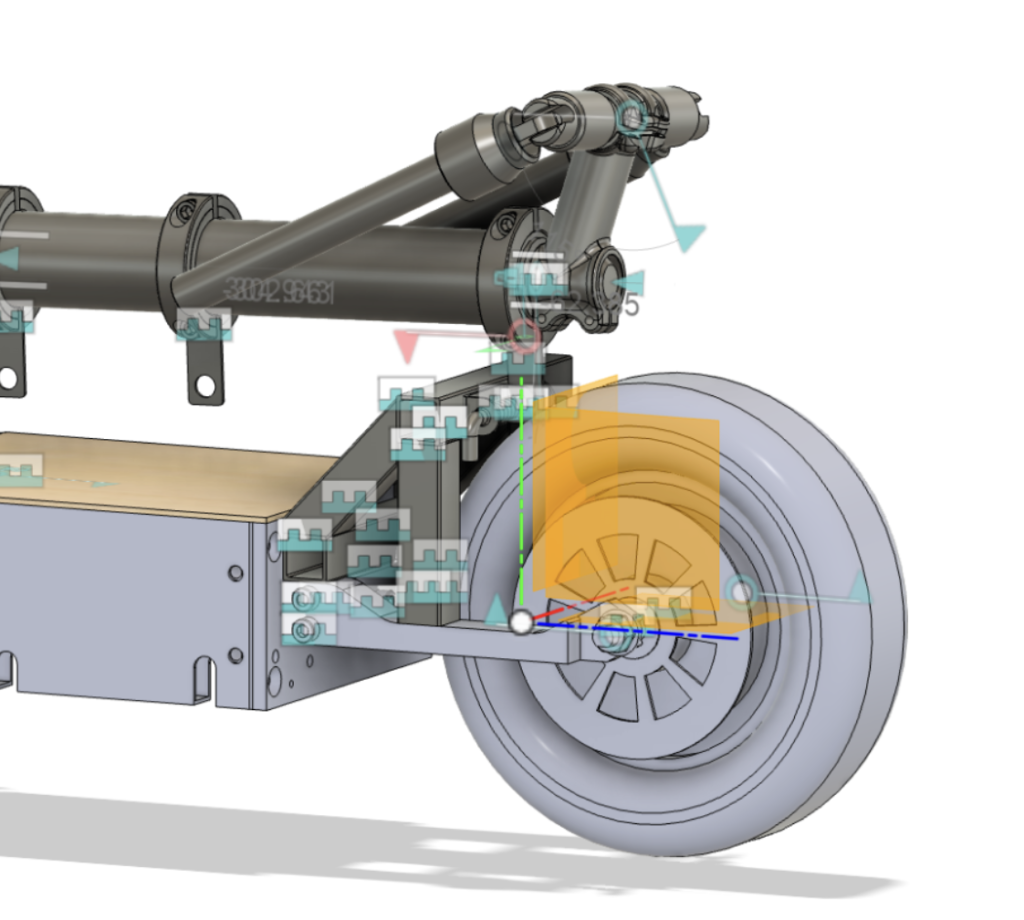

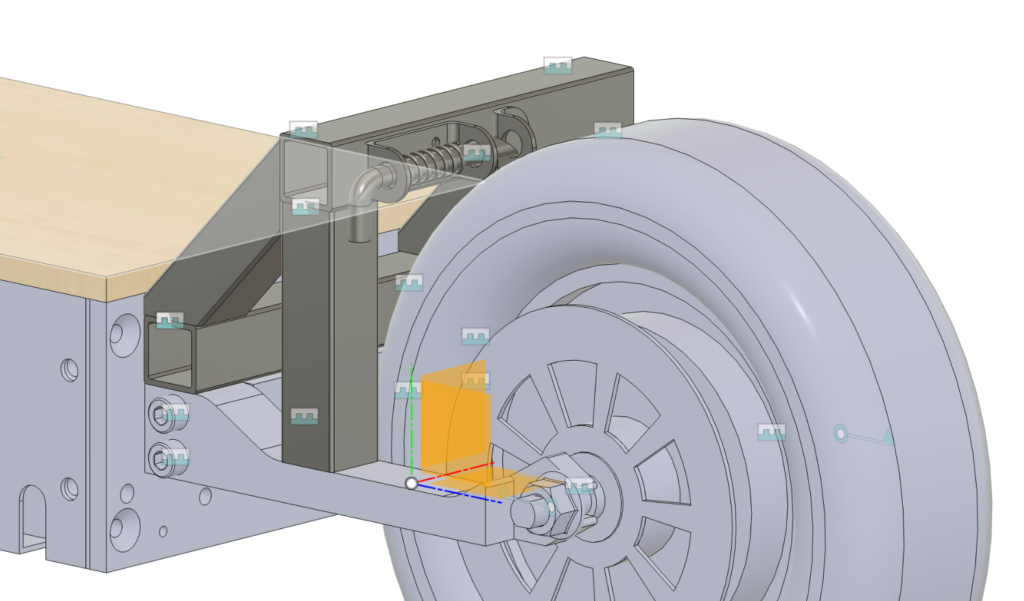

Utilizing Fusion 360, I modeled and simulated key elements of the scooter with custom-designed and off-the-shelf parts (models in the images have been greatly generalized). For a lot of the CAD, I favored off-the-shelf parts over custom designs to easily facilitate the physical manufacturing prototyping process. These CAD models are more focused on functionality and ensuring that–in the case of simulations–the safety factor is adequate.

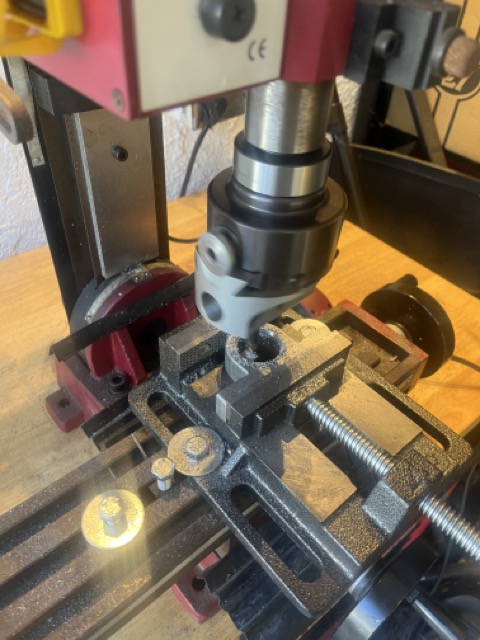

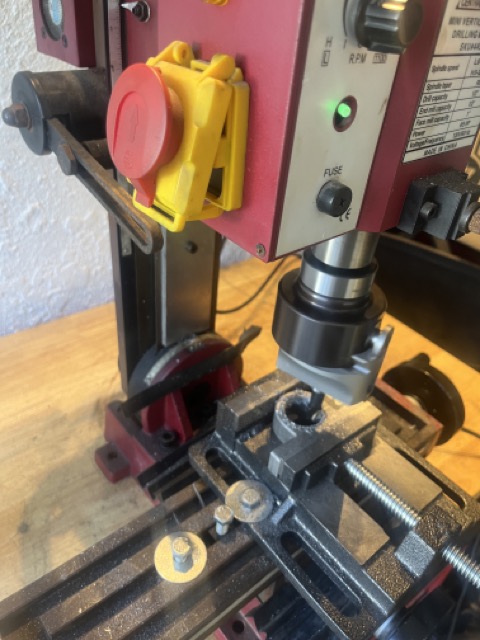

Machining

With a 3D printer and a sense of resourcefulness, I helped bring some of the sketches and CAD to life. My team utilized rapid prototyping and modified off-the-shelf pieces to create a functional scooter prototype.

Processes Utilized:

- Milling, Turning, Boring

- 3D Printing

- Cutting and Assembling

Key Takeaways

Organization

Throughout this experience, I focused extensively on my organizational abilities. I took the initiative to maintain a very thorough slide journal to log my daily achievements and takeaways. Each day, I updated the slides with specific agenda items, questions, and obstacles. This allowed me to keep a record of everything I had done, the respective timeline of which everything was completed, and to keep myself accountable for my work.

Simplification

Something that I came to terms with while working on this project was my instinct to immediately design at a high level. I initially struggled with being able to take a step back and understand the simplest components of what I was designing. I would try to design something for the end result, but needed to instead consider the most basic components that are necessary. As I continued to hone my simplification skills, I realized the broader range of designs that are possible from new perspectives.

Resourcefulness

Simplification also manifested in the way of resourcefulness. My instinct was to design a bunch of custom pieces to be utilized in not only the final design but also the prototyping stages. This was useful when I was 3D printing, but not so much when it came to replicating the designs with steel or aluminum–especially with experimental components when manufacturing steel or aluminum in custom geometries can be costly. I had to reframe my perspective and create similar geometries with off-the-shelf parts, taking the time and care to fully ensure that rapid prototypes are developed quickly and effectively.